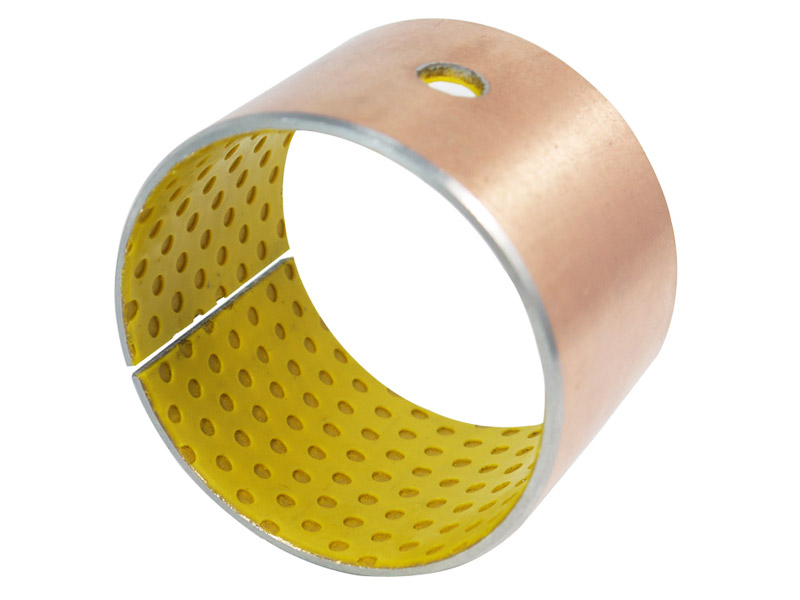

Sleeve bushing is a key component commonly used in mechanical equipment. Its design parameters have an important impact on the performance, life and maintenance costs of the equipment. In the design of sleep bushing, the four parameters S3, C0, Ci and β play a crucial role.

The S3 parameter usually indicates the outer diameter of sleeve bushing. The selection of this parameter needs to take into account the accuracy of the fit with the shaft or hole and the load it can bear. Compared with other similar products, sleep bushing's S3 parameters generally have higher accuracy and a wider selection range. This advantage allows sleep bushing to adapt to more different working environments and application scenarios, thereby improving the versatility and reliability of the equipment. However, high-precision S3 parameters also mean higher manufacturing costs and stricter processing requirements, which may increase the overall cost of the product.

The C0 parameter usually represents the radial clearance of sleeve bushing. The size of the C0 parameter directly affects the lubrication performance, wear rate and sealing performance of sleeve bushing. Compared with other similar products, the C0 parameter of sleep bushing usually has a smaller tolerance range, which means that the radial gap of sleep bushing is more uniform and stable. This advantage helps reduce friction and wear, improving equipment operating efficiency and longevity. Too small a C0 parameter may also lead to poor lubrication or difficulty in assembly, so it needs to be weighed according to specific conditions in actual applications.

The Ci parameter is the inner diameter size of sleeve bushing, which is closely related to the fitting accuracy of the shaft or hole. The Ci parameter control of sleeve bushing has high precision, which can ensure a close fit with the shaft, reduce vibration and wear, and improve the operational stability and service life of the equipment. The Ci parameter control of sleeve bushing has high precision, which can ensure a close fit with the shaft, reduce vibration and wear, and improve the operational stability and service life of the equipment. The Ci parameter control of sleeve bushing has high precision, which can ensure a close fit with the shaft, reduce vibration and wear, and improve the operational stability and service life of the equipment.

The β parameter represents the inclination angle or taper of sleeve bushing. The size of the β parameter directly affects the installation, disassembly and sealing performance of sleeve bushing. Appropriate beta parameters can make sleeve bushing easier to install on the shaft, reducing difficulties and risks during assembly. : The design of β parameter can affect the lubrication and sealing effect between the sleeve and the shaft. Reasonable tilt angle or taper helps to form a good lubricating oil film and reduce wear and leakage. The β parameter can also affect the stress distribution inside the bushing. A reasonable inclination angle or taper can make the stress distribution more uniform, reduce local stress concentration, and improve the durability of the bushing. By optimizing the β parameters, the installation process of sleeve bushing can be made smoother and more efficient, and assembly costs can be reduced. Reasonable β parameter design can improve the lubrication and sealing effect between the sleeve and the shaft, reduce friction, wear and leakage, and improve the operating efficiency and service life of the equipment. By adjusting the β parameter, the stress distribution inside the bushing can be made more uniform, the occurrence of stress concentration can be reduced, and the durability and reliability of the bushing can be improved. Its shortcoming is that the design of β parameters needs to consider multiple factors such as materials, loads, speeds, etc., so the design process is relatively complex and requires rich experience and professional knowledge. To achieve specific beta parameters, special manufacturing processes and processing equipment may be required, which may increase manufacturing costs. The β parameter design of sleeve bushing also needs to consider the matching problem with the axis. If the size or shape of the shaft does not match the sleeve, installation difficulties or reduced performance may result.

English

English Español

Español